|

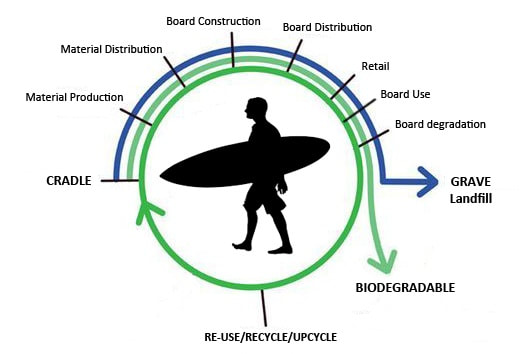

As surfers we should all have some degree of environmental sustainability hard-wired into us. It’s impossible to play in the ocean as we do and not feel a sense of responsibility towards its care and protection. Our eco-mindedness does however raise a few conundrums, as much of what we use to surf isn’t exactly earth or ocean friendly. Consider your wetsuits, boards and surf accessories. Do they tick any green boxes? Many surfers are innovators, and frustrated by the dichotomy of this they take their environmental awareness a step further. Like Boland surfer Brendan Basset. Brendan is passionate about surfing and passionate about the environment. For the last few years he has been doing extensive R&D into more enviro-friendly alternatives to the traditional polyurethane / polyester resin construction of surfboards. His journey towards the goal of improving the sustainability of surfboards has been an interesting one, and the outcome has certainly been slightly different from what he expected at the outset. Brendan, what got you started on the whole sustainability path? Was it through surfing? I completed an undergraduate degree in Material Science and Engineering, which basically taught me a great deal about all materials. Having been a surfer all my life, I started understanding that the materials used in the surf industry were in no way sustainable and as a consequence were negatively impacting the environment. This inspired me to start investigating what the sustainable alternatives were. Not many people manage to do their PhD on surfboards! Being able to combine a passion for surfing, sustainability and studying is a really cool achievement! Tell us a bit about that. I wanted to create a research project that investigated sustainable materials for the marine craft industry, and in doing so create an awareness of eco-friendly alternatives to current practice. The CSIR in Port Elizabeth provided me with the perfect opportunity, allowing me to conduct research on using natural fabrics (hemp/flax) in place of glass fabrics. You’ve been experimenting with flax and hemp as some of the materials you’re using. How do they compare to traditionally used materials? (Brendan started a company which offers surfboard lamination in sustainable resins and fibre.) The understanding of comparing two materials is quite complex. The typically question I am asked is: “Is it stronger?”. In the case of a surfboard, there are many types of strong: tensile, shear, compression, flexure, impact, adhesive etc. What I can breakdown from my research is: Natural fabrics are as “strong” as traditional glass with added impact strength. There is a slight increase in weight however, but this increase durability. To really answer the question fully, the comparison test has to be conducted over a wide range of surfboard sizes and shapes. Only then will we arrive at a definitive answer. Given you’ve using hemp cloth for glassing, how many guys have asked you if they can smoke their new stick!? Yes, too many times to count! You could equate it to asking a psychiatrist: “How does that make you feel?” It is a pity that most guys just see the humorous side of hemp, instead of understanding it’s viability as a sustainable alternative to it’s more toxic cloth equivalents. Any other bio-friendly materials you’ve looked at or are in the pipeline? Bio-friendly is a complicated term. Sustainability actually doesn’t necessarily equal bio-friendly. This is a vitally important construct to understand. Take Bio-resins for instance. They have a 30% bio-matter component, but this doesn’t mean it doesn’t harm the environment. Sustainability, bio-degradability and recyclability are very important terms to understand in the growth of improving the surf industry. Why is the concept of sustainability so important for the surfing industry? The concept of sustainability is as very important to the surf industry in general, as is recyclability and biodegradability. Sustainability is “off-setting” 100% virgin materials, reducing energy input during manufacture and sourcing materials that won’t be depleted. I actually regard recyclability as the most important characteristic, since a “sustainable” board can do just as much harm to the environment as traditional materials if not disposed of properly. If you’re going to just toss your broken “sustainable” board into the garbage, it’s pretty much the same as tossing your “normal” board away. The outcome of their full life-cycle is the same – they just both end up in landfill. This is where bio-degradation comes in. Almost all surfboards will not bio-degrade (or at least not for a very very long time), even when using bio-based materials. Even a sustainable board will not bio-degrade any faster than our current boards. This brings us to recyclability. We need to create awareness as to the ways in which we can recycle surfboards. The process to break down a bio-board into its component parts so that these can effectively be recycled is just too timeous, costly and difficult. It doesn’t make economic sense to do it, so right now no-one offers that. Thus the irony is that even though an eco-board might be made from recyclable materials, these hold little monetary value when recycled, and so they aren’t actually recycled. Thus the recyclability of an eco-board is more theoretical than practical at this stage. How does an eco-friendly board feel, ride and perform compared to a “normal” board? Feel, ride and performance is somewhat down to the individuals abilities, the type of surfboard, and waves they are riding. I am an above-average surfer that has been riding slightly heavier sustainable boards for 2-3 years now with no complaints. A well-known South African pro-freesurfer has ridden a couple of boards of mine with very positive feedback – he’s actually enjoyed the increased weight on a point break style wave compared to the top of the range traditional board. A log rider who wants a lot of weight would then be very interested in trying out boards made with natural fibres such as hemp, due to the slightly increased weight. Feel, ride and performance is very subjective and fortunately for traditional boards we have almost a century of testing. Sustainable boards are just coming into the picture and the full attributes of their feel, ride and performance have yet to be fully documented. Harder to snap or easier to snap? Literally and figuratively. My research has proven that the amount of force to snap a board in half is essentially the same for both an eco-board and a normal board. However, my testing was done on a machine that provides an understanding of mechanical properties in a controlled environment. The ocean is anything but a controlled environment! The performance of a board to do a “snap” manoeuvre is more dependent on the size and shape of the wave ridden. Smaller performance waves require a bit more agility compared to big hollow waves. Therefore, the ability to design different lay-ups with different fabrics is an advantage in achieving the right balance for each surfer riding a range of waves. There has been a move in the surf industry in recent years towards “green” products – but are these more marketing hoopla than green? “Green marketing” is definitely a thing. The ability to sell products at a higher price because the producer says they are greener is abundantly clear in all industries. For a manufacturer to say its “green or eco” has the effect on consumers to feel better about their purchase. This unfortunately leads to many misunderstandings as to what is essentially good or bad about the effect of the product on the environment. Why is the concept of sustainability so important for the surfing industry? Sustainability in the surf industry is two-fold. The industry has to step up and actually make a difference, as we now know that the majority of surf industry products are not good for the environment and we need to assume responsibility for this. However, the problem comes in with the ‘green marketing’ side of things. Many of the current “green” surf industry products that proclaim their sustainability or environmentally friendly characteristics don’t really live up to these claims when you examine the full life cycle of the product. Are eco-boards that much better? Where do they tick the green box, and where do they fail to do so. To be honest, no; they aren’t any better for the environment than normal boards at this stage. And that’s because you have to consider the entire life cycle of the board. Production is one thing, but it’s the end of the life cycle where it basically has the same outcome. Two examples of this are the bio-resin and eco-blanks. Bio-resin is basically normal resin with the use of plant matter as part of the resin. Despite the inclusion of plant matter, it doesn’t make the board better for the environment post-use or easier make it any easier to recycle. Eco-blanks are classified as having part recycled matter added to the normal blank. Again, despite being better from a manufacturing perspective in that one is using recycled materials, it also doesn’t make the product any different as it still ends up in landfill. So does that mean I should just stick to my regular stick? Yes and no. I’m not saying that sustainability doesn’t count for anything. It’s great that we are looking at more environmentally friendly ways to make things. What I am saying is that even the most sustainable board you find today doesn’t end up helping the environment much unless you find a way to recycle that board post-use. In actual fact, you would be better off recycling a normal board than buying a sustainable board and not recycling it. It really all comes down to understanding that it’s the end point of the life-cycle that’s the most important. We have to stop things ending up in landfill. Do you see a way that we’ll solve the recycling conundrum that seems to be the thorn in the side of eco-boards? Recycling surfboards is not only difficult, but the materials that come from the recycled board are of little value and thus not profitable. This is why we don’t see many people doing this when ultimately it is the most essential contribution to the environment that we could actually make. Eco-boards only represent a small fraction of the market at present, do you see this changing? With an eco-blank and bio-resins costing up to three times that of a normal product, I don’t see the popularity of eco-boards changing that much. Most surfers are cost conscious! To reiterate, buying an eco-board at a greater expense without recycling it is kind of missing the point. It’s the full life-cycle of an item that makes the difference in the outcome. You’ve personally evolved your philosophy around eco-boards as you’ve begun producing them, and now question whether they will make indeed make a difference overall? My initial objective to produce surfboards using sustainable materials was more to gauge the market, to understand the validity and viability of doing it, so but also to use it as a platform to inform the surf industry of the effect of their products on the environment. Unfortunately once I really started to understand and appreciate the very limited impact on the overall life cycle that the eco-materials and eco-manufacturing aspect was having, I just had to step back from a moral perspective. The materials are one thing, but the waste of production is a complete different story. Every stroke of sand paper that touches the foam or resin is creating micro-plastics that will end up in a landfill or ocean if it is not recycled. It would be disingenuous to try claim that eco-boards were as green as they claimed to be. You’re still passionate about making an impact on the environment, so where to from here? I’ve evolved my philosophy through this whole journey, and am now looking to try create a bigger-picture impact by focussing on the composite industry as a whole. My research up till now has focused on how natural fibres will benefit composite products. I would like to continue expanding on this so that we can find a ways in which the production of these natural fibre-based composite materials can minimise their impact on the environment throughout their entire life cycle. Meaning we get the last part of the lifecycle right – the recycling. And then of course looking to see if we can then incorporate these materials in the surfboard industry! Recycle materials that actually are practically recyclable. Ed's note: Speaking at length to Brendan really opened my eyes as to the challenge of trying to have an eco-board tick all three boxes - sustainability, recyclability and biodegradability. So far no-one has got the holy trilogy right. You can make the board from recycled product, but then what happens when it goes to landfill - its gonna hang around there for a 1000 years. Or fine, make it from wood - that will biodegrade - but then is it sustainable to be cutting down trees for surfboards? Therein lies the conundrum. (*and by the way - recycled blanks only actually contain about 30% recycled material...) Contact Brendan Basset for more info or further discussion [email protected]

Comments are closed.

|

AuthorMillerslocal Archives

July 2021

|

RSS Feed

RSS Feed