|

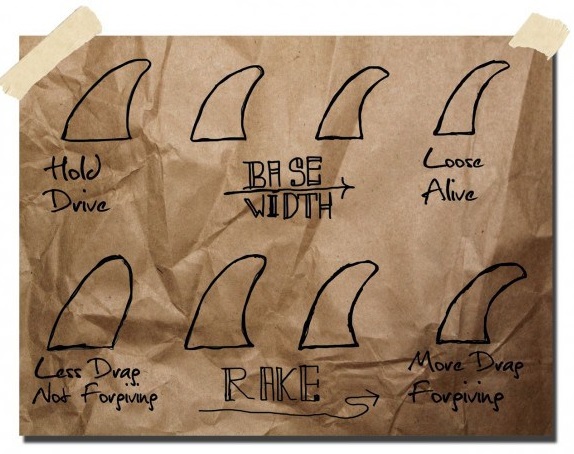

Local shaper guru Dennis Ellis drops us a lil article on fins and fin systems. From 1 through to 5, and FCS to Futures...gotcha all covered. By Dennis Ellis Fins are important little bits of your surfboard. If you’ve ever knocked one out while surfing, you’ll know just how important. Think of them as the tyres of a car. They give traction, control your speed and help you through direction changes. If you’re driving a Ferrari, there’s no point in putting on cheap retreads, and if you drive a rusted old Isuzu bakkie, it’s silly to put Pirelli’s on all four wheels at 2 grand a pop. What I’m saying is, choose the fin and fin system that best suits your surfboard, your abilities and the type of surf you ride. If you’re a beginner, you’re going to be whacking them out, get cheapies. Cheap and nasty. Don’t worry too much about the type of system, you’ll break them all. And here’s a fact about fins, if you crack them really hard on something, reef, sand or your mates head, they’re going to come out. Even if they’re glassed on. The original fin systems were designed for the fin to snap off without damaging plugs or board, but this seldom happens, the forces and variety of angles are just too great. The real advantages of the systems though, are traveling and changing a board’s performance with different size and shape fins. It really does make a difference and this is the beauty of fin systems. With 3 different types of fins, you can essentially have 3 boards in one. Like anything, the way you look after your direction finding friends will dictate their lifespan. Check that they’re still tight from time to time. If you come to a grinding halt on a wave by riding into something, at least give them a wiggle afterwards to see that they’re not going anywhere. Taking your fins out after every surf isn’t a good idea. It’s fun, but adds to the wear and tear on moving parts. Everything has a lifespan, make those little grubscrews last as long as possible. Cos they sure can be a mission when they strip. Most stripped grub screw problems are normally because of a bad or overused fin key. So before trying any other option try and get hold of a brand new fin key, it maximizes the chances of grabbing hold. If that doesn't work get an Allen key of slightly larger size than your regular fin key. If still no luck and no fin is in the plug, try using a small drill bit, following the same direction as the screw being careful not to damage the thread of the plug. Hopefully the grub screw may exit the plug. Nothing worked? Bring it to us...we'll fix it! Fin Stiffness: When a fin bends, some of the drive you are trying to translate from your feet to your board is lost, and you’ll have a slight wafting feeling, especially off the bottom on a fair sized wave. In small surf this can be fun, tailsliding and all. But if the surf is serious you need a fin with serious stiffness/and or a bit more area. Fin Size: There are so many different fin shapes out there, its mind numbing. Don’t bother too much with the rake, tip etc. The main aspect is the surface area of the fin. Big for big people or waves, small for tiny people and tiny waves. Big fins will give you drive and tighten your board, small fins will make it loose and decrease drive. Fin Number: 1,2,3 or 4. Or 5

These characteristics are general, they can vary hugely by fin positions and sizes. You have plastic injection molded fins (the bottom of the range FCS, Futures & Gas fins etc), which are flexible and cheap. Then you have fibreglass molded fins such as Gas & Scarfini. They're much stiffer fins at a good price. Lastly, you get the fibreglass CNC fins like the Kinetic Racing, certain FCS & Future models, and Maisch. These are all super stiff, but have a higher price tag. Boxes/system types So many out there, ironically the most popular (F.C.S twin tab),are not always the strongest or best. That title probably goes, or went to O’Fish’l, a brilliant single box under glass system which didn’t have grub screws. They are no longer around but have morphed into Futures, with a single grub screw. Simple, strong and light. But a nightmare to get (cheap) replacement fins and the fins are pretty pricey. The new FCS II, which doesn't require a grub screw looks really interesting too. Just click it in and you're good to go. No doubt with a hefty price tag though. Every board has an ideal fin, and they can vary from board to board. Play around a bit. Start with a big fin and get smaller until it clicks. Change them in different conditions to get the most out of your board. Keep the system the same in all your boards, and most important, don’t ride into stuff (especially people). PS - ever wondered why sometimes your fins hum? Simply put, pressure differences result in turbulence, which results in vibration, which gives you the hum.

Here's a great explanations from Swaylock's Forum, by a reader called Kirk: "As water flows around a fin there are different pressures on each side of the fin. Water flows meet up at the trailing edge of the fin, and in cases with very different pressures, vortices or turbulence can be generated. These vortices push and pull on the trailing edge of the fin, causing it to vibrate. This vibration creates pressure waves or sound. Think of it as your voice when you blow air across your vocal cords. Have you noticed that your fins hum at certain points while you are surfing, for example during a bottom turn on a fast wave? The vibration hum can be amplified or louder in cases of resonance. In fin terms resonance happens when the pushing and pulling from the vortices causes the fins trailing edge to move back and forth how it wants to move naturally. Or more technically, resonance can be defined as the circumstance when the force applied to the system is equal to the damping or resistance of the system at the systems natural frequency. How do you fix it? Sand the sides of the trailing edge with a 100-150 grit sand paper (give it a few passes) and then surf it, if it still hums then give it a few more passes with the sand paper. The idea is to minimize the pressure difference at the trailing edge by sanding off any imperfections that may have been left from the production process. Make sure you don't sand too much, the more you sand, the sharper and more dangerous the trailing edge gets." Comments are closed.

|

AuthorMillerslocal Archives

July 2021

|

RSS Feed

RSS Feed