|

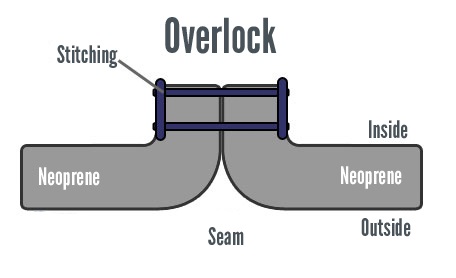

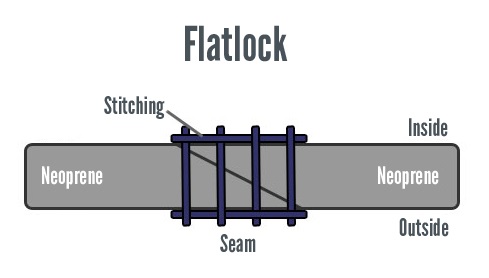

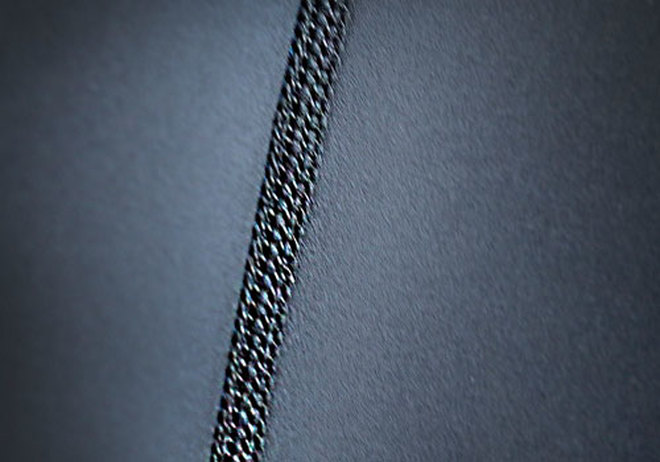

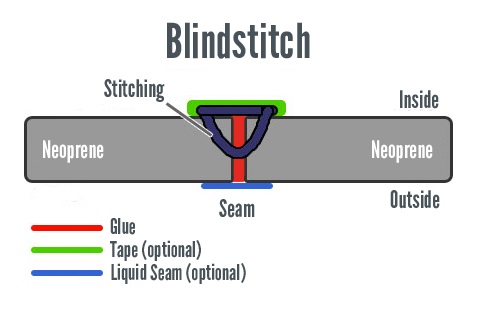

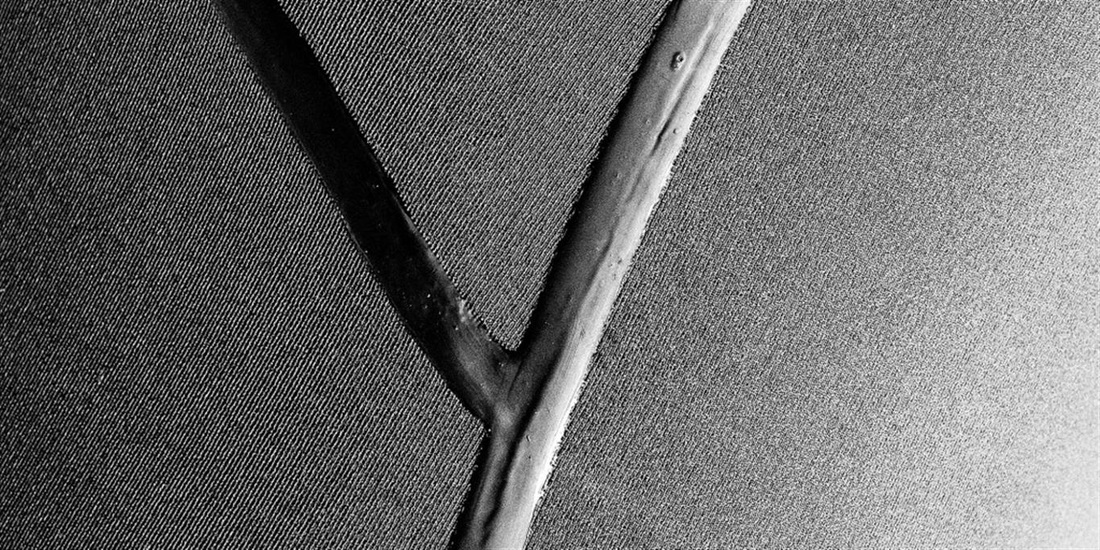

The difference between a smile and a scowl as you walk into the water for that winter sesh is all in the seams. Sure, you get all types of fancy-ass neoprene these days, but it's how those panels are put together that really counts when the temperature drops. Cos not all seams are created equal. Stitching a wettie together involves making holes in the neoprene and passing a thread through in order to hold the panels together. The hiccup is that these holes can let water (and wind) in though the waterproof neoprene, so the type of stitching is an important consideration for how warm your suit will be. Less holes equals a warmer wettie occupant. Stitches aren't as flexible as neoprene either - so the more stitches the less stretch you're gonna have. OVERLOCKED These seams are found in the low-end or summer suits cos it's the simplest way of stitching. The two edges of the neoprene are pinched together and then stitched, leaving a nice big ridge on the inside of the wettie to chafe the crap out of you. Plus they leak water in like a sieve. And they're about as flexible as a stone. Basically just your bargain basement cheap and kinda-nasty stitch that's fine for mini-groms cos they ain't fussy 'bout stuff like that. FLATLOCK The flatlock stitch looks like a miniature railroad and can easily be identified by its zig-zag close stitched seams. It involves laying one panel edge over the other, then stitching though the neoprene with multiple needles in a series of three or four rows of stitching, creating a very strong seam which is pretty flexy. But cos the process entails creating so many holes, it is prone to letting water in. Flatlock stitching is mainly found in entry-level suits, being better suited to warm water surfing cos of the flush-factor. The value-for-money kinda stitch. GLUED AND BLIND-STITCHED (GBS) First the neoprene is glued together. The first layer of glue seals the neoprene, the second layer of glue is the adhesive to bond wetsuit panels together. Some brands triple glue their neoprene in the belief that more is better. Is that third layer of glue any better? Dunno. Then a curved needle brings the thread through the neoprene in such way that it exits on the same side that it went in, without punching through. That's why it's called ‘blind’ because the needle never penetrates the neoprene completely, so there are no holes. The result is a watertight stitch. So far so good. But for every ying there's a yang. The elasticity of the neoprene is different from the elasticity of the glue. Salt water and sun can crack the glue up and open the stitch from the inside. So warm it is for sure, but durability can sometimes be an issue. Many manufacturers put tape on the inside of the seams to reinforce them and stop this from happening GBS WITH TAPE Suits can be Spot Taped or Fully Taped. Spot Taping is when tape is glued to the inside of the seam in critical areas to add additional strength where needed. Fully Taped Seams are when tape is glued to the inside of every seam. That means no opening of the stitches and no water. Lekker. But this is a very time consuming process, and time is money. So expect more damage to the piggy bank. And not all tape is created equal. You can get basic tape, or waterproof tape and now even neoprene tape. The neoprene tape means zero loss in flexibility as the tape stretches just as much as the neoprene. LIQUID SEALED OR FLUID WELDED SEAMS A few names exist for this type of seam, but it's really just different ways of describing the same thing. The neoprene is glued together, and then a silicon-based urethane seal (a rubber strip basically) is applied over the top. No holes from stitching means no water can get it and you stay warm and toasty. The advantage of this is that the wetsuit will be more flexible as when the suit is stretched the seam will stretch with it. Double whammy bonus is that it makes the suit airtight. Blow into the arm of any liquid sealed suit and you’ll find it blows up like a balloon and will not release the air. That means the suit is airtight - and if it's airtight, it's watertight. You get suits with the rubber strip applied to one side of the seam, while a double fluid seam weld with have the rubber strip applied to both sides of the seam inside and out. Liquid seams are the best thing since sliced bread. But even sliced bread goes mouldy. And liquid sealed seams have their downside too. None of the main wettie manufacturers have been able to perfect the silicon yet - and the seals will eventually crack, split and peel off over time. Some quicker than others. And your suit goes from hero to zero as suddenly the water starts seeping in and the edges of the cracked seams chow your ass and inner thighs. But ysss, it's lekker while it lasts! Used to refuse to surf in anything other than double liquid sealed seam wetties cos am seriously allergic to cold water, but for some obscure reason the newer liquid seals are not lasting nearly as well as the old one's and after getting ripped to pieces by a fraying liquid seam on one of my older suits I have been trying out single welded seams as well as GBS with full waterproof taping - and both are just as warm.

Funnily enough whatever they made the original liquid seals out of worked way better than the newer versions, cos still have a Billabong Solution Gold that I got back in 2007 whose liquid seams are perfect, and a few 2012 O'Neill Psycho II's that are also still in great nick. Hopefully future advancements will see liquid seals that last as long as the neoprene panels they join together! Which will make surfing line-up's like these a breeze. Sort of. Comments are closed.

|

AuthorMillerslocal Archives

July 2021

|

RSS Feed

RSS Feed